-

sales@tujinmagnet.com

-

+86-18858010843

Neo Block Countersunk Magnets for Door & Window is a magnetic connector designed for doors and windows. Made of high-quality Neodymium magnetic material, combined with a rectangular appearance and countersunk design, this magnet not only provides a strong magnetic adsorption force, but also ensures that it will not damage the overall aesthetics of the door and window after installation. It is very suitable for scenes where a strong connection is required but the magnetic components are not exposed.

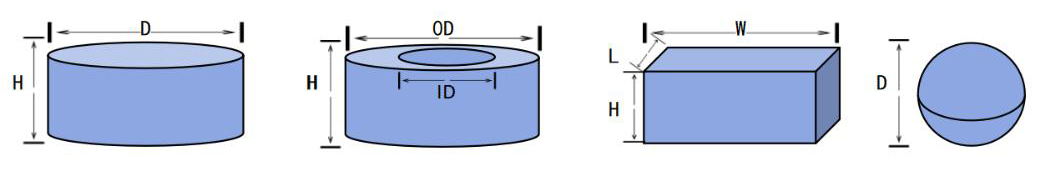

Shape and size:

Neo Block Countersunk Magnets for Door & Window is designed as a rectangle with a regular shape and rounded corners to prevent scratches or damage to the contact surface. The moderate length and a size of a few centimeters are suitable for the installation needs of most doors and windows. Two circular holes are provided at both ends for easy installation and fixing by screws or other fasteners.

Color and gloss:

The surface is silver or gray, which is due to the natural gloss produced by the high-quality magnetic material and its coating treatment. The reflective performance is good, showing a certain metallic texture, adding to the overall aesthetics.

Countersunk design:

The unique countersunk structure ensures that the magnet can be embedded in the door and window frame flatly after installation, without bulging, keeping the door and window smooth and neat.

High-performance magnetic material:

The use of high-performance NdFeB magnetic material ensures the durability and strong magnetic adsorption of the magnet. It can provide a stable magnetic connection to ensure that doors and windows are tightly closed in various situations.

Easy to install and disassemble:

The countersunk design and the setting of the circular hole allow the magnet to be easily installed on the door and window frame with screws or other fasteners. When necessary, it can also be easily disassembled for replacement or repair.

Application scenarios

Home doors and windows: As a magnetic connector, it can realize the rapid closure and positioning of doors and windows, and increase the overall beauty and practicality.

Commercial places: Used for doors and windows that need to be opened and closed frequently, improve convenience and reduce noise.

Exhibition halls and museums: Provide invisible and stable support and connection for display cabinets, glass partitions, etc.

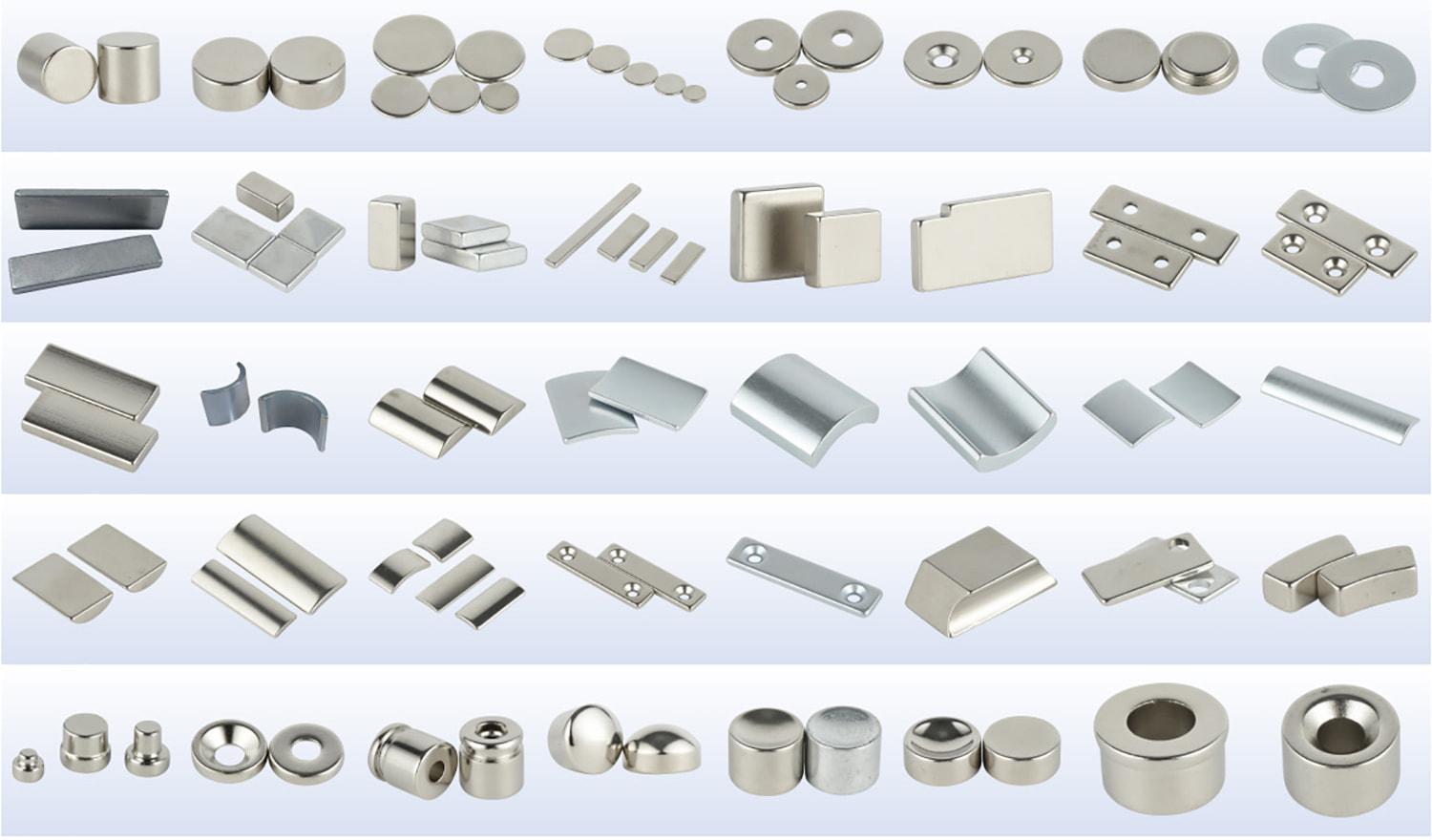

Products show

Surface Coating & Corrosoin Resistance

|

|

|

|

| Nickel(Ni-Cu-Ni) | Zinc(Zn) | Black Epoxy | Gold |

| Type | Color | Plating Thickness | Working Temperature |

Advantage & Suitable | Salt Spray Resistance | |||||

| Nickel(NiCuNi) | silver | 20-30 um | ≤200 | high oxidation resistance, good glossiness, stable performance, long service life | > 72 hrs | |||||

| Zinc (Zn) | blue white | 10-20 um | ≤160 | suitable for low requirements for surface appearance & oxidation resistance | > 48 hrs | |||||

| Epoxy | black | 10-30 um | ≤120 | suitable for high anti-corrosion and strict atmospheric environment | > 96 hrs | |||||

| Gold | Gold | 5-30 um | ≤200 | suitable for decoration accessories, gift box etc. | > 24 hrs | |||||

Tolerance

| Standard Product | D.OD | ID | L | W | H |

| <5mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm |

| <10mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm |

| <20mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm |

| <50mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm |

| <100mm | ±0.15mm | ±0.15mm | ±0.15mm | ±0.15mm | ±0.15mm |

| >100mm | ±0.2mm | ±0.2mm | ±0.2mm | ±0.2mm | ±0.2mm |

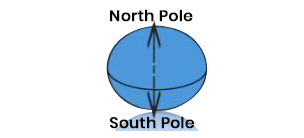

Magnetization Direction

| Disc&Cylinder-through Thickness | Disc&Cylinder-through Diameter | Spheres- through Diameter |

|

Poles on the flat surfaces

|

Poles on the side surfaces |

|

| Block- through Thickness | Block- through Length | Arc- through Diamter |

|

Poles on the larger flat surfaces |

Poles on the smaller flat surfaces |

Poles on outside&inside faces |

| Arc- through Length | Ring- through Surfaces | Ring- through Surfaces |

|

Poles on outside&inside faces |

Planar octupole magnetization |

Planar quadrupole magnetization |

Sintered NdFeB Magnetic Properties

| Grade | Remanence | Coercive Force | Intrinsic Coercivity | Maximum Energy | Working≤ | |||||||

| Br(KG) | Br(T) | Hcb (KOe) |

Hcb (KA/m) |

Hcj (KOe) |

Hcj (KA/m) |

(BH)max(MGOe) | (BH)max (KJ/ m) |

℃ | ||||

| Max | Min | Max | Min | |||||||||

| N35 | ≥11.8 | ≥1.18 | ≥10.8 | ≥860 | ≥12 | ≥960 | 37 | 33 | 295 | 263 | N | ≤80 |

| N38 | ≥12.3 | ≥1.23 | ≥10.8 | ≥860 | ≥12 | ≥960 | 39 | 36 | 310 | 287 | ||

| N40 | ≥12.7 | ≥1.27 | ≥11.0 | ≥876 | ≥12 | ≥960 | 41 | 38 | 327 | 302 | ||

| N42 | ≥13.0 | ≥1.30 | ≥11.0 | ≥876 | ≥12 | ≥960 | 43 | 40 | 343 | 320 | ||

| N45 | ≥13.3 | ≥1.33 | ≥11.0 | ≥876 | ≥12 | ≥960 | 46 | 42 | 366 | 335 | ||

| N48 | ≥13.7 | ≥1.37 | ≥10.5 | ≥836 | ≥12 | ≥960 | 49 | 45 | 390 | 358 | ||

| N50 | ≥14.0 | ≥1.40 | ≥10.5 | ≥836 | ≥12 | ≥960 | 51 | 47 | 406 | 374 | ||

| N52 | ≥14.2 | ≥1.42 | ≥10.5 | ≥836 | ≥12 | ≥960 | 53 | 49 | 422 | 390 | ||

| N54 | ≥14.4 | ≥1.44 | ≥10.5 | ≥836 | ≥11 | ≥876 | 55 | 51 | 438 | 406 | ||

| N35M | ≥11.8 | ≥1.18 | ≥10.8 | ≥860 | ≥14 | ≥1114 | 37 | 33 | 295 | 263 | M | ≤100 |

| N38M | ≥12.3 | ≥1.23 | ≥11.0 | ≥876 | ≥14 | ≥1114 | 39 | 36 | 310 | 287 | ||

| N40M | ≥12.7 | ≥1.27 | ≥11.5 | ≥915 | ≥14 | ≥1114 | 41 | 38 | 327 | 302 | ||

| N42M | ≥13.0 | ≥1.30 | ≥11.8 | ≥939 | ≥14 | ≥1114 | 43 | 40 | 343 | 320 | ||

| N45M | ≥13.3 | ≥1.33 | ≥12.0 | ≥956 | ≥14 | ≥1114 | 46 | 42 | 366 | 335 | ||

| N48M | ≥13.7 | ≥1.37 | ≥12.2 | ≥972 | ≥14 | ≥1114 | 49 | 45 | 390 | 358 | ||

| N50M | ≥14.0 | ≥1.40 | ≥12.5 | ≥995 | ≥14 | ≥1114 | 51 | 47 | 406 | 374 | ||

| N52M | ≥14.2 | ≥1.42 | ≥12.5 | ≥995 | ≥14 | ≥1114 | 53 | 49 | 422 | 390 | ||

| N33H | ≥11.4 | ≥1.14 | ≥10.6 | ≥844 | ≥17 | ≥1350 | 35 | 31 | 279 | 247 | H | ≤120 |

| N35H | ≥11.8 | ≥1.18 | ≥10.8 | ≥860 | ≥17 | ≥1350 | 37 | 33 | 295 | 263 | ||

| N38H | ≥12.3 | ≥1.23 | ≥11.0 | ≥876 | ≥17 | ≥1350 | 39 | 36 | 310 | 287 | ||

| N40H | ≥12.7 | ≥1.27 | ≥11.5 | ≥916 | ≥17 | ≥1350 | 41 | 38 | 327 | 302 | ||

| N42H | ≥13.0 | ≥1.30 | ≥11.8 | ≥940 | ≥17 | ≥1350 | 43 | 40 | 343 | 320 | ||

| N45H | ≥13.3 | ≥1.33 | ≥12.0 | ≥955 | ≥17 | ≥1350 | 46 | 42 | 366 | 335 | ||

| N48H | ≥13.6 | ≥1.36 | ≥12.2 | ≥971 | ≥17 | ≥1350 | 49 | 45 | 390 | 358 | ||

| N50H | ≥14 | ≥1.4 | ≥12.5 | ≥995 | ≥17 | ≥1350 | 51 | 47 | 406 | 374 | ||

| N52H | ≥14.3 | ≥1.43 | ≥12.5 | ≥995 | ≥17 | ≥1350 | 53 | 49 | 422 | 390 | ||

| N33SH | ≥11.4 | ≥1.14 | ≥10.6 | ≥844 | ≥20 | ≥1592 | 35 | 31 | 279 | 247 | SH | ≤150 |

| N35SH | ≥11.8 | ≥1.18 | ≥10.8 | ≥860 | ≥20 | ≥1592 | 37 | 33 | 295 | 263 | ||

| N38SH | ≥12.3 | ≥1.23 | ≥11.0 | ≥876 | ≥20 | ≥1592 | 39 | 36 | 310 | 287 | ||

| N40SH | ≥12.6 | ≥1.26 | ≥11.5 | ≥916 | ≥20 | ≥1592 | 41 | 38 | 327 | 302 | ||

| N42SH | ≥12.9 | ≥1.29 | ≥11.8 | ≥940 | ≥20 | ≥1592 | 43 | 40 | 343 | 320 | ||

| N45SH | ≥13.2 | ≥1.32 | ≥12.0 | ≥955 | ≥20 | ≥1592 | 46 | 42 | 366 | 335 | ||

| N48SH | ≥13.6 | ≥1.36 | ≥12.2 | ≥971 | ≥20 | ≥1592 | 49 | 45 | 390 | 358 | ||

| N50SH | ≥14 | ≥1.4 | ≥12.5 | ≥995 | ≥20 | ≥1592 | 51 | 47 | 406 | 374 | ||

| N33UH | ≥11.4 | ≥1.14 | ≥10.6 | ≥844 | ≥25 | ≥1990 | 35 | 31 | 279 | 247 | UH | ≤180 |

| N35UH | ≥11.8 | ≥1.18 | ≥10.8 | ≥860 | ≥25 | ≥1990 | 37 | 33 | 295 | 263 | ||

| N38UH | ≥12.3 | ≥1.23 | ≥11.0 | ≥876 | ≥25 | ≥1990 | 39 | 36 | 310 | 287 | ||

| N40UH | ≥12.6 | ≥1.26 | ≥11.5 | ≥916 | ≥25 | ≥1990 | 41 | 38 | 327 | 302 | ||

| N42UH | ≥12.9 | ≥1.29 | ≥11.8 | ≥940 | ≥25 | ≥1990 | 43 | 40 | 343 | 320 | ||

| N45UH | ≥13.2 | ≥1.32 | ≥12.0 | ≥955 | ≥25 | ≥1990 | 46 | 42 | 366 | 335 | ||

| N48UH | ≥13.6 | ≥1.36 | ≥12.2 | ≥971 | ≥25 | ≥1990 | 49 | 45 | 390 | 358 | ||

| N28EH | ≥10.4 | ≥1.04 | ≥9.50 | ≥756 | ≥30 | ≥2388 | 30 | 26 | 239 | 207 | EH | ≤200 |

| N30EH | ≥10.8 | ≥1.08 | ≥9.50 | ≥756 | ≥30 | ≥2388 | 32 | 28 | 255 | 223 | ||

| N33EH | ≥11.4 | ≥1.14 | ≥10.6 | ≥844 | ≥30 | ≥2388 | 35 | 31 | 279 | 247 | ||

| N35EH | ≥11.8 | ≥1.18 | ≥10.8 | ≥860 | ≥30 | ≥2388 | 37 | 33 | 295 | 263 | ||

| N38EH | ≥12.3 | ≥1.23 | ≥11.0 | ≥876 | ≥30 | ≥2388 | 39 | 36 | 310 | 287 | ||

| N40EH | ≥12.6 | ≥1.26 | ≥11.5 | ≥916 | ≥30 | ≥2388 | 41 | 38 | 327 | 302 | ||

| N42EH | ≥12.9 | ≥1.29 | ≥11.8 | ≥940 | ≥30 | ≥2388 | 43 | 41 | 343 | 320 | ||

| N45EH | ≥13.2 | ≥1.32 | ≥12.0 | ≥955 | ≥30 | ≥2388 | 46 | 42 | 366 | 335 | ||

| N30TH | ≥10.8 | ≥1.08 | ≥9.50 | ≥756 | ≥35 | ≥2786 | 32 | 28 | 255 | 223 | TH | ≤220 |

| N33TH | ≥11.4 | ≥1.14 | ≥10.6 | ≥844 | ≥35 | ≥2786 | 35 | 31 | 279 | 247 | ||

| N35TH | ≥11.8 | ≥1.18 | ≥11.0 | ≥876 | ≥35 | ≥2786 | 37 | 33 | 295 | 263 | ||

| N38TH | ≥12.2 | ≥1.22 | ≥11.0 | ≥876 | ≥33 | ≥2627 | 39 | 36 | 310 | 287 | ||

| Remarks: The maximum working temperature depends on the shape, size, and coating of the magnet, the highest working temperature in the table is the test data for standard sample. | ||||||||||||

NdFeB magnets (Neodymium-iron-boron magnets) are primarily graded based on their maximum energy prod...

READ MORESimply put, the strongest magnetic force on a bar magnet is at its two ends, namely the magnetic pol...

READ MOREIn modern industry, NdFeB magnets are known as the "King of Magnets" due to their exceptional magnet...

READ MOREIn modern industry and daily life, ring magnets, as a type of permanent magnet material with a uniqu...

READ MOREIn modern science and industry, there is a material known as the "King of Magnets," possessing aston...

READ MOREOn the surface, disk magnets, with their solid center, seem to contain more magnetic material. Howev...

READ MOREMagnetic materials play a crucial role in modern industry and high-tech fields. Among them, neodymiu...

READ MOREDisc magnets, as a common type of permanent magnet, play an important role in our daily lives due to...

READ MOREDisc magnets are becoming increasingly common in our daily lives and industrial sectors due to their...

READ MOREMagnetic materials play a crucial role in modern technology and industry, with Neodymium magnet disk...

READ MOREIn the field of permanent magnet materials, neodymium magnets dominate due to their powerful magneti...

READ MOREIn our daily lives, magnets are present everywhere, from the simple refrigerator clips that hold not...

READ MORE