-

sales@tujinmagnet.com

-

+86-18858010843

EV Motor NdFeB Magnet for Electric Vehicle is a neodymium iron boron (NdFeB) magnet designed for electric vehicle (EV) motors. As one of the core components of electric vehicle motors, this magnet provides efficient and reliable driving force for electric vehicles with its excellent magnetic properties and stable physical properties.

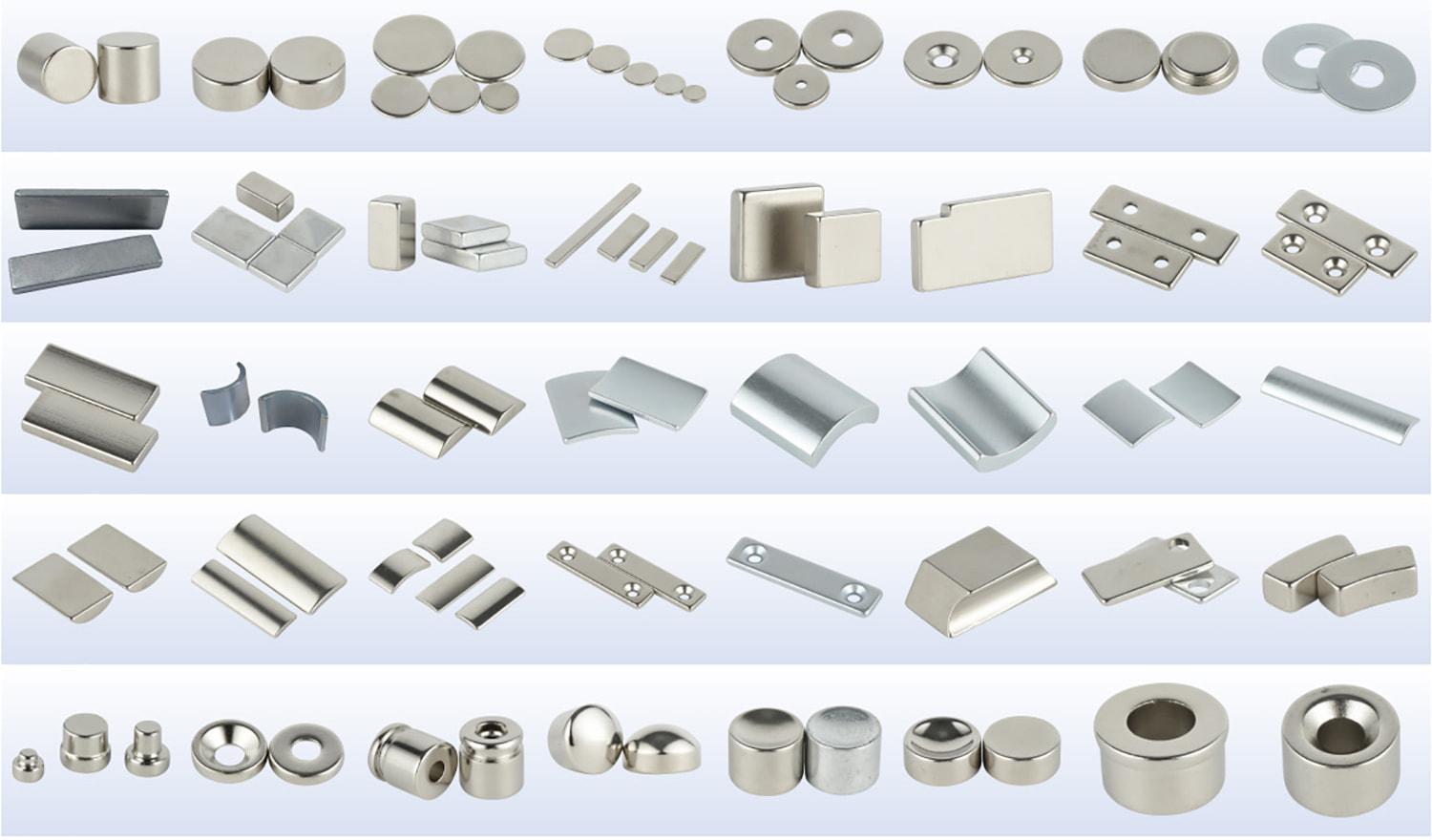

Shape and size:

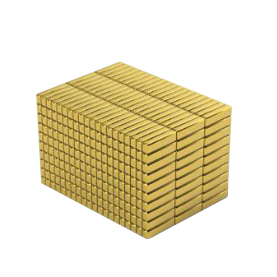

EV Motor NdFeB Magnet for Electric Vehicle is a regular rectangular or oblong shape, and the specific size is customized according to the needs of electric vehicle motors.

The surface of the magnet is smooth and the edges are neat, showing high-quality craftsmanship.

Color and texture:

The color of the magnet is silver-gray, which is the typical color of NdFeB magnets. The surface has a metallic luster and feels hard and smooth, showing its strong and durable characteristics.

Structural features:

EV Motor NdFeB Magnet for Electric Vehicle has a complex magnetic domain structure inside, which can provide a strong magnetic field to meet the requirements of electric vehicle motors for high magnetic energy product and coercive force. The magnetic poles of the magnet are evenly distributed, ensuring that a stable magnetic field can be generated in the motor and improving the operating efficiency of the motor.

High-efficiency energy conversion:

EV Motor NdFeB Magnet for Electric Vehicle can efficiently convert electrical energy into mechanical energy, improving the operating efficiency of electric vehicle motors.

Reduce energy loss and extend the range of electric vehicles.

Lightweight design:

EV Motor NdFeB Magnet for Electric Vehicle has high density and strength, which can reduce the weight of the motor while ensuring performance. It helps to reduce the overall weight of electric vehicles and improve the energy efficiency and handling of the vehicle.

Products show

Surface Coating & Corrosoin Resistance

|

|

|

|

| Nickel(Ni-Cu-Ni) | Zinc(Zn) | Black Epoxy | Gold |

| Type | Color | Plating Thickness | Working Temperature |

Advantage & Suitable | Salt Spray Resistance | |||||

| Nickel(NiCuNi) | silver | 20-30 um | ≤200 | high oxidation resistance, good glossiness, stable performance, long service life | > 72 hrs | |||||

| Zinc (Zn) | blue white | 10-20 um | ≤160 | suitable for low requirements for surface appearance & oxidation resistance | > 48 hrs | |||||

| Epoxy | black | 10-30 um | ≤120 | suitable for high anti-corrosion and strict atmospheric environment | > 96 hrs | |||||

| Gold | Gold | 5-30 um | ≤200 | suitable for decoration accessories, gift box etc. | > 24 hrs | |||||

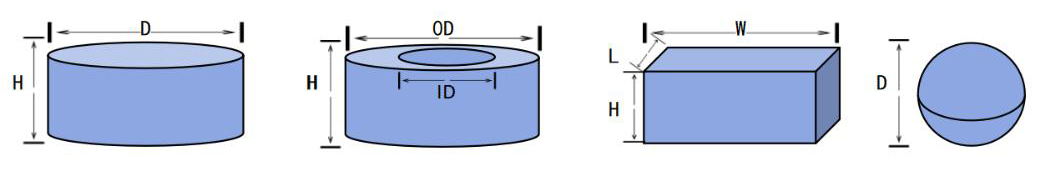

Tolerance

| Standard Product | D.OD | ID | L | W | H |

| <5mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm |

| <10mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm |

| <20mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm |

| <50mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm |

| <100mm | ±0.15mm | ±0.15mm | ±0.15mm | ±0.15mm | ±0.15mm |

| >100mm | ±0.2mm | ±0.2mm | ±0.2mm | ±0.2mm | ±0.2mm |

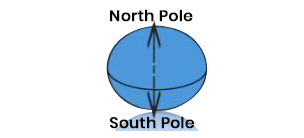

Magnetization Direction

| Disc&Cylinder-through Thickness | Disc&Cylinder-through Diameter | Spheres- through Diameter |

|

Poles on the flat surfaces

|

Poles on the side surfaces |

|

| Block- through Thickness | Block- through Length | Arc- through Diamter |

|

Poles on the larger flat surfaces |

Poles on the smaller flat surfaces |

Poles on outside&inside faces |

| Arc- through Length | Ring- through Surfaces | Ring- through Surfaces |

|

Poles on outside&inside faces |

Planar octupole magnetization |

Planar quadrupole magnetization |

Sintered NdFeB Magnetic Properties

| Grade | Remanence | Coercive Force | Intrinsic Coercivity | Maximum Energy | Working≤ | |||||||

| Br(KG) | Br(T) | Hcb (KOe) |

Hcb (KA/m) |

Hcj (KOe) |

Hcj (KA/m) |

(BH)max(MGOe) | (BH)max (KJ/ m) |

℃ | ||||

| Max | Min | Max | Min | |||||||||

| N35 | ≥11.8 | ≥1.18 | ≥10.8 | ≥860 | ≥12 | ≥960 | 37 | 33 | 295 | 263 | N | ≤80 |

| N38 | ≥12.3 | ≥1.23 | ≥10.8 | ≥860 | ≥12 | ≥960 | 39 | 36 | 310 | 287 | ||

| N40 | ≥12.7 | ≥1.27 | ≥11.0 | ≥876 | ≥12 | ≥960 | 41 | 38 | 327 | 302 | ||

| N42 | ≥13.0 | ≥1.30 | ≥11.0 | ≥876 | ≥12 | ≥960 | 43 | 40 | 343 | 320 | ||

| N45 | ≥13.3 | ≥1.33 | ≥11.0 | ≥876 | ≥12 | ≥960 | 46 | 42 | 366 | 335 | ||

| N48 | ≥13.7 | ≥1.37 | ≥10.5 | ≥836 | ≥12 | ≥960 | 49 | 45 | 390 | 358 | ||

| N50 | ≥14.0 | ≥1.40 | ≥10.5 | ≥836 | ≥12 | ≥960 | 51 | 47 | 406 | 374 | ||

| N52 | ≥14.2 | ≥1.42 | ≥10.5 | ≥836 | ≥12 | ≥960 | 53 | 49 | 422 | 390 | ||

| N54 | ≥14.4 | ≥1.44 | ≥10.5 | ≥836 | ≥11 | ≥876 | 55 | 51 | 438 | 406 | ||

| N35M | ≥11.8 | ≥1.18 | ≥10.8 | ≥860 | ≥14 | ≥1114 | 37 | 33 | 295 | 263 | M | ≤100 |

| N38M | ≥12.3 | ≥1.23 | ≥11.0 | ≥876 | ≥14 | ≥1114 | 39 | 36 | 310 | 287 | ||

| N40M | ≥12.7 | ≥1.27 | ≥11.5 | ≥915 | ≥14 | ≥1114 | 41 | 38 | 327 | 302 | ||

| N42M | ≥13.0 | ≥1.30 | ≥11.8 | ≥939 | ≥14 | ≥1114 | 43 | 40 | 343 | 320 | ||

| N45M | ≥13.3 | ≥1.33 | ≥12.0 | ≥956 | ≥14 | ≥1114 | 46 | 42 | 366 | 335 | ||

| N48M | ≥13.7 | ≥1.37 | ≥12.2 | ≥972 | ≥14 | ≥1114 | 49 | 45 | 390 | 358 | ||

| N50M | ≥14.0 | ≥1.40 | ≥12.5 | ≥995 | ≥14 | ≥1114 | 51 | 47 | 406 | 374 | ||

| N52M | ≥14.2 | ≥1.42 | ≥12.5 | ≥995 | ≥14 | ≥1114 | 53 | 49 | 422 | 390 | ||

| N33H | ≥11.4 | ≥1.14 | ≥10.6 | ≥844 | ≥17 | ≥1350 | 35 | 31 | 279 | 247 | H | ≤120 |

| N35H | ≥11.8 | ≥1.18 | ≥10.8 | ≥860 | ≥17 | ≥1350 | 37 | 33 | 295 | 263 | ||

| N38H | ≥12.3 | ≥1.23 | ≥11.0 | ≥876 | ≥17 | ≥1350 | 39 | 36 | 310 | 287 | ||

| N40H | ≥12.7 | ≥1.27 | ≥11.5 | ≥916 | ≥17 | ≥1350 | 41 | 38 | 327 | 302 | ||

| N42H | ≥13.0 | ≥1.30 | ≥11.8 | ≥940 | ≥17 | ≥1350 | 43 | 40 | 343 | 320 | ||

| N45H | ≥13.3 | ≥1.33 | ≥12.0 | ≥955 | ≥17 | ≥1350 | 46 | 42 | 366 | 335 | ||

| N48H | ≥13.6 | ≥1.36 | ≥12.2 | ≥971 | ≥17 | ≥1350 | 49 | 45 | 390 | 358 | ||

| N50H | ≥14 | ≥1.4 | ≥12.5 | ≥995 | ≥17 | ≥1350 | 51 | 47 | 406 | 374 | ||

| N52H | ≥14.3 | ≥1.43 | ≥12.5 | ≥995 | ≥17 | ≥1350 | 53 | 49 | 422 | 390 | ||

| N33SH | ≥11.4 | ≥1.14 | ≥10.6 | ≥844 | ≥20 | ≥1592 | 35 | 31 | 279 | 247 | SH | ≤150 |

| N35SH | ≥11.8 | ≥1.18 | ≥10.8 | ≥860 | ≥20 | ≥1592 | 37 | 33 | 295 | 263 | ||

| N38SH | ≥12.3 | ≥1.23 | ≥11.0 | ≥876 | ≥20 | ≥1592 | 39 | 36 | 310 | 287 | ||

| N40SH | ≥12.6 | ≥1.26 | ≥11.5 | ≥916 | ≥20 | ≥1592 | 41 | 38 | 327 | 302 | ||

| N42SH | ≥12.9 | ≥1.29 | ≥11.8 | ≥940 | ≥20 | ≥1592 | 43 | 40 | 343 | 320 | ||

| N45SH | ≥13.2 | ≥1.32 | ≥12.0 | ≥955 | ≥20 | ≥1592 | 46 | 42 | 366 | 335 | ||

| N48SH | ≥13.6 | ≥1.36 | ≥12.2 | ≥971 | ≥20 | ≥1592 | 49 | 45 | 390 | 358 | ||

| N50SH | ≥14 | ≥1.4 | ≥12.5 | ≥995 | ≥20 | ≥1592 | 51 | 47 | 406 | 374 | ||

| N33UH | ≥11.4 | ≥1.14 | ≥10.6 | ≥844 | ≥25 | ≥1990 | 35 | 31 | 279 | 247 | UH | ≤180 |

| N35UH | ≥11.8 | ≥1.18 | ≥10.8 | ≥860 | ≥25 | ≥1990 | 37 | 33 | 295 | 263 | ||

| N38UH | ≥12.3 | ≥1.23 | ≥11.0 | ≥876 | ≥25 | ≥1990 | 39 | 36 | 310 | 287 | ||

| N40UH | ≥12.6 | ≥1.26 | ≥11.5 | ≥916 | ≥25 | ≥1990 | 41 | 38 | 327 | 302 | ||

| N42UH | ≥12.9 | ≥1.29 | ≥11.8 | ≥940 | ≥25 | ≥1990 | 43 | 40 | 343 | 320 | ||

| N45UH | ≥13.2 | ≥1.32 | ≥12.0 | ≥955 | ≥25 | ≥1990 | 46 | 42 | 366 | 335 | ||

| N48UH | ≥13.6 | ≥1.36 | ≥12.2 | ≥971 | ≥25 | ≥1990 | 49 | 45 | 390 | 358 | ||

| N28EH | ≥10.4 | ≥1.04 | ≥9.50 | ≥756 | ≥30 | ≥2388 | 30 | 26 | 239 | 207 | EH | ≤200 |

| N30EH | ≥10.8 | ≥1.08 | ≥9.50 | ≥756 | ≥30 | ≥2388 | 32 | 28 | 255 | 223 | ||

| N33EH | ≥11.4 | ≥1.14 | ≥10.6 | ≥844 | ≥30 | ≥2388 | 35 | 31 | 279 | 247 | ||

| N35EH | ≥11.8 | ≥1.18 | ≥10.8 | ≥860 | ≥30 | ≥2388 | 37 | 33 | 295 | 263 | ||

| N38EH | ≥12.3 | ≥1.23 | ≥11.0 | ≥876 | ≥30 | ≥2388 | 39 | 36 | 310 | 287 | ||

| N40EH | ≥12.6 | ≥1.26 | ≥11.5 | ≥916 | ≥30 | ≥2388 | 41 | 38 | 327 | 302 | ||

| N42EH | ≥12.9 | ≥1.29 | ≥11.8 | ≥940 | ≥30 | ≥2388 | 43 | 41 | 343 | 320 | ||

| N45EH | ≥13.2 | ≥1.32 | ≥12.0 | ≥955 | ≥30 | ≥2388 | 46 | 42 | 366 | 335 | ||

| N30TH | ≥10.8 | ≥1.08 | ≥9.50 | ≥756 | ≥35 | ≥2786 | 32 | 28 | 255 | 223 | TH | ≤220 |

| N33TH | ≥11.4 | ≥1.14 | ≥10.6 | ≥844 | ≥35 | ≥2786 | 35 | 31 | 279 | 247 | ||

| N35TH | ≥11.8 | ≥1.18 | ≥11.0 | ≥876 | ≥35 | ≥2786 | 37 | 33 | 295 | 263 | ||

| N38TH | ≥12.2 | ≥1.22 | ≥11.0 | ≥876 | ≥33 | ≥2627 | 39 | 36 | 310 | 287 | ||

| Remarks: The maximum working temperature depends on the shape, size, and coating of the magnet, the highest working temperature in the table is the test data for standard sample. | ||||||||||||

When selecting NdFeB ring magnets, size and magnetic force are the two most critical factors. Genera...

READ MORENdFeB magnets (Neodymium-iron-boron magnets) are primarily graded based on their maximum energy prod...

READ MORESimply put, the strongest magnetic force on a bar magnet is at its two ends, namely the magnetic pol...

READ MOREIn modern industry, NdFeB magnets are known as the "King of Magnets" due to their exceptional magnet...

READ MOREIn modern industry and daily life, ring magnets, as a type of permanent magnet material with a uniqu...

READ MOREIn modern science and industry, there is a material known as the "King of Magnets," possessing aston...

READ MOREOn the surface, disk magnets, with their solid center, seem to contain more magnetic material. Howev...

READ MOREMagnetic materials play a crucial role in modern industry and high-tech fields. Among them, neodymiu...

READ MOREDisc magnets, as a common type of permanent magnet, play an important role in our daily lives due to...

READ MOREDisc magnets are becoming increasingly common in our daily lives and industrial sectors due to their...

READ MOREMagnetic materials play a crucial role in modern technology and industry, with Neodymium magnet disk...

READ MOREIn the field of permanent magnet materials, neodymium magnets dominate due to their powerful magneti...

READ MORE